The choice of material for paper collated framing nails can significantly impact both the weight and strength of the collated nails. The primary materials used for manufacturing framing nails include steel and, less commonly, stainless steel or other alloys.

Here’s how the choice of material can affect the weight and strength of paper collated framing nails:

- Steel Nails:

- Weight: Steel is a dense and relatively heavy material. As a result, paper collated framing nails made of steel tend to be heavier compared to nails made from lighter materials.

- Strength: Steel is known for its high tensile strength and durability. Steel framing nails provide strong and reliable fastening, making them suitable for various construction applications.

- Stainless Steel Nails:

- Weight: Stainless steel is generally lighter than carbon steel, but the weight difference may not be significant for small fasteners like framing nails.

- Strength: Stainless steel offers corrosion resistance, which is advantageous in outdoor or corrosive environments. However, the strength of stainless steel is generally slightly lower than that of carbon steel.

- Alloyed Materials:

- Weight: Depending on the specific alloy used, the weight of alloyed framing nails may vary. Some alloys are designed to be lighter than traditional steel while maintaining strength.

- Strength: Alloyed materials can be tailored to provide specific strength characteristics. Certain alloy compositions can offer enhanced strength or other desirable properties.

- Composite Materials:

- Weight: Composite materials may be used in some specialized framing nails to reduce weight. These materials can include a combination of fibers, polymers, and other additives.

- Strength: The strength of composite materials can be engineered to meet the requirements of framing applications, but it may not always match the strength of traditional steel.

- Titanium Nails:

- Weight: Titanium is known for its lightweight nature. Framing nails made from titanium can be significantly lighter than their steel counterparts.

- Strength: Titanium offers a good strength-to-weight ratio, but its strength may not be as high as that of certain steel alloys. Titanium is often chosen for its corrosion resistance and lightness.

It’s important to consider the specific requirements of a construction project when choosing the material for paper collated framing nails. Factors such as the type of wood or material being fastened, environmental conditions, and the desired balance between weight and strength will influence the selection of framing nail materials. paper collated framing nails Additionally, adherence to industry standards and building codes is crucial to ensuring that the chosen framing nails meet the necessary structural requirements for the intended application.

What are the key differences between paper collated framing nails and wire-collated or paper-collated nails?

It seems there might be a slight confusion in the question, as both “wire-collated” and “paper-collated” are mentioned together. Typically, nails are collated using one of these methods, and the choice between wire or paper collation refers to how the nails are held together in a strip for use in pneumatic nail guns.

Let me provide information on both paper and wire collation:

1. Paper Collated Framing Nails:

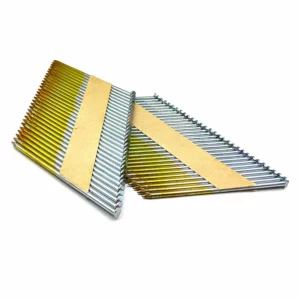

- Collation Method: In paper collation, the framing nails are held together in a strip with a paper tape.

- Advantages:

- Paper collation is often preferred for its environmental friendliness, as paper is biodegradable.

- The paper tape can be easily and cleanly removed after installation.

- Applications:

- Paper collated framing nails are commonly used in construction, framing, and other applications where a strong, secure bond between the nail strip and the nails is essential.

2. Wire Collated Framing Nails:

- Collation Method: In wire collation, framing nails are held together with wire.

- Advantages:

- Wire collation is known for its durability and ability to withstand rough handling during transportation and use.

- The wire strip provides stability to the nails, preventing them from falling apart before being driven into the material.

- Applications:

- Wire collated framing nails are often used in high-volume, heavy-duty applications where the durability of the collation is crucial, such as in industrial or manufacturing settings.

It’s important to note that the collation method (paper or wire) primarily relates to how the nails are arranged and held together for efficient use with pneumatic nail guns. The choice between paper and wire collated framing nails depends on factors such as the application, the specific requirements of the job, and personal preferences.

If you meant to compare paper collated framing nails with another type of collation (other than wire), or if there’s additional clarification needed, please provide more details so I can offer more precise information.