A peristaltic tube pump, also known as a peristaltic hose pump or peristaltic pump, is a type of positive displacement pump that operates by squeezing and releasing a flexible tube or hose to move fluid. The pump uses a rotating mechanism, often in the form of rollers or shoes, to compress the tube against a fixed housing or casing.

The primary purpose of a peristaltic tube pump is to transfer or dispense fluids without coming into direct contact with the pump mechanism. The fluid is contained within the flexible tube, and as the rotating mechanism compresses the tube, it creates a series of discrete sealed chambers along its length. These chambers move along the tube, pushing the fluid forward in a pulsating manner.

Peristaltic tube pumps offer several advantages and find applications in various fields, including:

- Gentle Fluid Handling: Peristaltic tube pumps provide gentle fluid handling as the fluid is only in contact with the flexible tubing. This makes them suitable for transferring delicate, shear-sensitive, or viscous fluids without causing damage or degradation.

- Contamination Prevention: The fluid being pumped remains entirely within the tubing, eliminating the risk of contamination or cross-contamination between different fluids. This feature makes peristaltic tube pumps ideal for transferring sensitive or hazardous fluids, as well as for applications where sterility is essential.

- Accurate and Repeatable Flow: Peristaltic tube pumps offer precise control over the flow rate since it is directly proportional to the rotational speed and the size of the tubing. This accuracy and repeatability make them suitable for applications requiring precise dosing or metering of fluids.

- Easy Maintenance and Cleanability: Peristaltic tube pumps have a simple design with easily replaceable tubing, making maintenance and cleaning relatively straightforward. The tubing can be quickly replaced, reducing downtime and minimizing the risk of contamination.

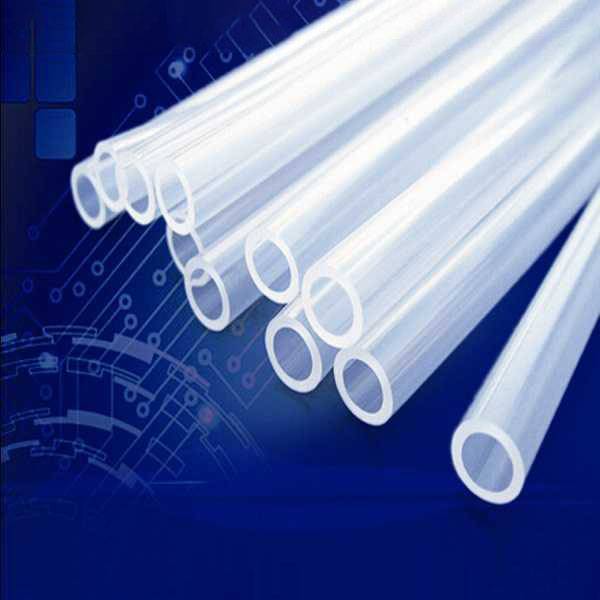

- Versatility and Fluid Compatibility: Peristaltic tube pumps can handle a wide range of fluids, including corrosive, abrasive, viscous, or sensitive fluids. The choice of tubing material can be tailored to the specific fluid being pumped, ensuring compatibility and minimizing the risk of chemical reactions or material degradation.

Peristaltic tube pumps find applications in various industries and sectors, including:

- Pharmaceutical and Biotechnology: They are used for drug delivery, media and buffer transfer, cell culture, chromatography, and filling operations in pharmaceutical manufacturing and biotechnology applications.

- Food and Beverage: Peristaltic tube pumps are employed in food and beverage production for the transfer of ingredients, flavorings, additives, and delicate fluids that require gentle handling and accurate dosing.

- Environmental and Water Treatment: They are used in water and wastewater treatment processes for dosing chemicals, transferring samples, and laboratory-scale applications.

- Chemical and Industrial Processes: Peristaltic tube pumps find use in chemical processing, industrial automation, and process control applications, such as dosing chemicals, transferring abrasive or corrosive fluids, and metering precise quantities.

- Research and Laboratory: They are utilized in research laboratories for various tasks, including fluid transfer, sample preparation, chemical dosing, and experimental setups.

Peristaltic tube pumps offer a reliable and versatile solution for fluid transfer and metering applications, particularly when precise dosing, contamination prevention, and gentle handling of fluids are required.

Here is some more information

- Laboratory and Research Applications: Peristaltic tube pumps are widely used in laboratory and research settings. They are employed for various tasks, including fluid transfer, sample preparation, chemical dosing, and experimental setups. Peristaltic pumps offer precise control over flow rates, allowing researchers to accurately dispense fluids and conduct experiments requiring controlled fluid delivery.

- Water and Wastewater Treatment: Peristaltic tube pumps play a significant role in water and wastewater treatment processes. They are used for dosing chemicals, such as disinfectants or pH adjusters, into water treatment systems. Peristaltic pumps provide accurate and consistent dosing, ensuring the appropriate chemical concentrations for effective treatment.

- Printing and Inkjet Systems: Peristaltic tube pumps are utilized in printing and inkjet systems. They are responsible for delivering ink or other fluids to the print head or nozzle. The precise control and pulsation-free flow of peristaltic pumps ensure consistent and accurate printing, with minimal risk of clogging or contamination.

- Analytical Instruments: Peristaltic tube pumps find applications in analytical instruments, such as liquid chromatography (LC) systems and spectrophotometers. They are used for sample and solvent delivery, allowing for precise control over the flow rate and accurate measurements in analytical processes.

- Industrial Processing: Peristaltic tube pumps are employed in various industrial processes that require accurate fluid transfer or dosing. They are used for tasks such as filling containers, transferring chemicals, dispensing additives, and metering precise quantities in manufacturing operations.

- Food and Beverage Industry: Peristaltic tube pumps play a vital role in the food and beverage industry. They are used for transferring ingredients, flavorings, and additives in food and beverage production. Peristaltic pumps provide gentle handling and accurate dosing, ensuring the integrity and quality of the final products.

- Mining and Mineral Processing: Peristaltic tube pumps find applications in the mining and mineral processing industry. They are used for transferring chemicals, reagents, and slurries in various stages of mineral extraction and processing. The robust construction and resistance to abrasive fluids make peristaltic pumps suitable for the demanding conditions of mining operations.

- Oil and Gas Industry: Peristaltic tube pumps are utilized in the oil and gas industry for various applications, including chemical injection, well stimulation, and sample analysis. They offer precise and controlled fluid delivery in harsh and hazardous environments.

- Agriculture and Irrigation: Peristaltic tube pumps find applications in agriculture and irrigation systems. They are used for accurately dosing fertilizers, pesticides, and other agricultural chemicals, ensuring precise and controlled distribution for optimal crop growth and yield.

Peristaltic tube pumps are favored in many industries due to their ability to provide accurate fluid transfer, gentle handling, and contamination-free operation. They offer versatility, reliability, and ease of maintenance, making them a valuable tool in numerous applications where precise fluid delivery is essential. The choice of tubing material, pump size, and control features can be tailored to meet specific requirements and ensure optimal performance in each application.